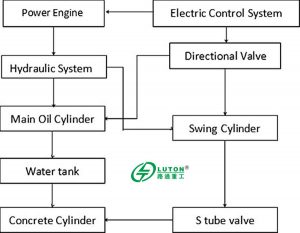

Concrete pump is a combination equipment of multiple function unites. Each function unit is consisted of many components. These parts cooperate with each other, controlled by the central control unit. The control unit centralized the working mode and the process of each part. Thus, the final function is realized by close cooperation. In this way, concrete pump will complete each kind of concrete pumping task.

The next three minutes, I will take you through the whole working process of a concrete pump. Ready for getting the working principle of a concrete pump.

Step 1 Raw materials Feeding

The first step of the concrete pump is to inject concrete liquid into the pump body. But for different types of concrete pumps, the content of this work is also different.

For concrete mixing pump, in fact, before the liquid concrete is conveyed to the pump body by the mixer, the materials are added from the aggregate, cement, water and so on.

Raw materials such as aggregate and cement are added into the mixer by the loading truck, and water is usually added by a pump and a time relay. According to the pre-designed feeding time, the electric controlling unit controls the amount of raw materials to be added, so as to achieve a more accurate proportion and meet the needs of various engineering materials.

When the sensor detects that the raw materials have reached the preseted number value, it will send a signal to the PLC controller. After receiving the signal, PLC will issue instructions to close the packing door.

The mixing drum is then driven by the main engine and hydraulic motor to thoroughly and evenly mix the measured materials.

After the mixing time stops, PLC will issue instructions again to open the unloading hatch door, then the liquid concrete will be unloaded into the concrete cylinder, waiting to be pumped.

Click here for more details on concrete mixing pump.

For concrete pump trailer, without concrete mixing unit, so the concrete must be fed by another single mixer truck. The working process is relatively simple. That is, concrete liquid is ready mixed in the mixer truck can be fed into the concrete cylinder directly.

Step2 Concrete Pumping

Concrete Pumping is the crucial process of the whole pump. That is also the main function of a concrete pump. It seems like a simple process but that is realized by a series of complex device cooperation.

There are some crucial parts which will help you to get the principle of the working process of the whole system.

First of all, the concrete feeding hopper. It is the place where concrete is fed and also the place where concrete is pumping out. Because the pumping outlet is installed in and through the concrete feeding hopper.

In concrete hopper, there is a hydraulic swing cylinder in which the swing rod is installed. Driven by swing hydraulic system, the swing rod moves left and right continuously to make the glass plate move left and right, finally realize the pumping outlet connecting the two concrete cylinder alternately. Why there are two concrete cylinder? That is to fulfill the continuous concrete pumping.

Now, let’s have a look at the concrete cylinder. Concrete is sucked into a concrete cylinder, meanwhile in the other one, concrete is pushing out into the pipeline.

The movement of sucking and pushing are all realized by concrete rods, which are connected with the hydraulic rods in the hydraulic cylinders driven by hydraulic energy system.

Power hydraulic energy plus the directional control valve block make the two rods in hydraulic cylinders work alternatively and coordinately.

The control of the oil circuit is the key of the cooperation of the two cylinders.

Then, the cooperation between the swing rods and the pumping rods. The movement of the swing rods and the pumping rods are relative closely. Actually, each time the pumping rods reach to the maximum stroke means one pumping process is over. And the swing rod acts to exchange the connection. That is the start of the next pumping.

In this way, the concrete pumping work can be continuously completed. …Read more.